GIS Drives Digital Transformation of Maintenance at Mazoon Electricity Company (MZEC) in Oman

Mazoon Electricity Company (MZEC) is a closed Omani joint stock company. It distributes electricity to half a million customers over 75,000 square kilometres in the Ad Dakhiliyah, Ash Sharqiyah South, Ash Sharqiyah North, and Al Batinah South governorates as well as to Al Suwaiq in the Al Batinah North governorate. MZEC was founded in 2005 after the privatization of the Ministry of Housing, water, and Electricity. Since the privatization, MZEC has focused on innovation, modernization, and digital transformation.

MZEC Office in Sur, Ash Sharqiyah South Governorate

MZEC Office in Sur, Ash Sharqiyah South Governorate

Challenge

Among the areas that MZEC needed to modernize were the workflows of electric asset inspection and maintenance. The challenge was that the use of paper forms dominated. This legacy process created issues for the modernization effort. Maintenance reports were inaccurate, outdated, and incomplete. Paper forms and manually prepared checklists were often lost or misplaced. At times, insects and rodents would damage the forms, making them illegible and resulting in repeat field visits and thus wasted effort. The paper forms required filing and storage, resulting in space issues. Access and retrieval efforts were time-consuming and ineffective. Analysis of the results of inspection and maintenance was tedious at best. Managers could not guarantee data quality.

MZEC’s legacy paper-based maintenance process inhibited innovation.

MZEC’s legacy paper-based maintenance process inhibited innovation.

At MZEC, 141 teams—composed of more than 500 employees and contractors—work in field maintenance activities. It was difficult to manage and monitor their performance without a consistent process and means of managing the data. No system or database was available to manage outdoor maintenance activities. Various departments, including assets, maintenance, and geographic information system (GIS) teams, were involved in the process.

Workflows required paper forms in binders.

Workflows required paper forms in binders.

Solution

MZEC turned to its comprehensive GIS for a solution based on ArcGIS. While MZEC had an outstanding GIS, it lacked an innovative mobile solution. However, with innovation, careful thought, and a study of the maintenance workflows, management was convinced that a mobile GIS approach would not only meet but exceed expectations in modernizing the maintenance and inspection workflows in their entirety.

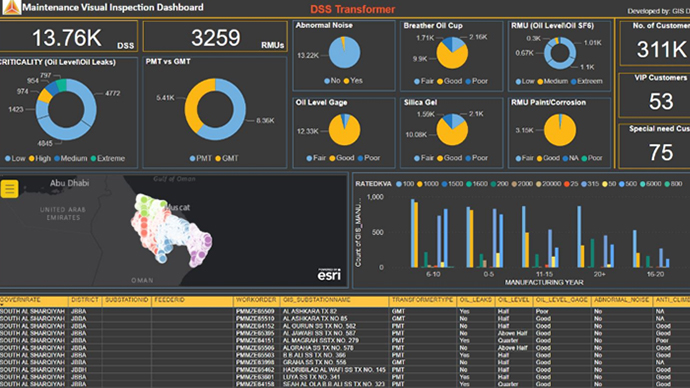

ArcGIS has several mobile applications that can display electric asset details as well as apps that collect data through smart forms and populate the enterprise GIS. In addition, it provides secure access to GIS content through the web using ArcGIS Enterprise. Finally, the GIS team integrated ArcGIS with a workflow modelling system, Make, and Microsoft Power BI to streamline and standardize MZEC’s maintenance and inspection processes.

ArcGIS provides the means to share and analyze the collected information about asset status and display the results using ArcGIS Dashboards and integrated Power BI dashboards.

Power BI Integrated with ArcGIS

Power BI Integrated with ArcGIS

“Today, GIS is considered a powerful platform that can be used to implement enterprise integrated solutions due to the integration capabilities of ArcGIS Enterprise products with many systems and services such as MS [Microsoft] Power BI, Make, Tableau, and MS Power Automate. By utilizing those systems’ capabilities together, we get great outcomes and results with low cost and high benefits.”

Talal Al Abdali, Head of GIS Support, MZEC

The Solution Summary

- Created over 100 digitized checklists of all inspection and maintenance tasks

- Collected data from the field using ArcGIS mobile solutions

- Generated survey reports and uploaded them and their attachments to OneDrive with a specific folder structure through Make’s scenarios

- Analyzed and presented the collected information through ArcGIS Dashboards and Microsoft Power BI

- Used Esri technology including ArcGIS Pro, ArcGIS Enterprise, portal, server, web adaptor, and data, ArcGIS Dashboards, ArcGIS Survey123, ArcGIS Collector, and ArcGIS Field Maps

PROJECT PHASES

Analysis—Analyzed paper checklists and discussed and recorded the complete scenario and requirements for the solution in preparation for the design and implementation phase

Design and implementation—Designed and implemented the survey forms and reports based on the analysis results; created web maps, Make scenarios, and OneDrive folder structure

Operation and support—Tested and deployed the solution to make it available for end users, monitored their performance, resolved their issues, and created a user manual and communication channel to report

Reports and dashboards—Used the collected data to create dashboards and reports that support decision-making and share them with users and decision-makers

“Report filing time was reduced by one-third. One primary substation previously consumed 80 to 100 pages of A4 size paper, but now all the data resides in a secure digital location.”

Laith Al Yahmedi, Head of Maintenance at Ash Sharqiyah North Governorate

Results

Data inaccuracy, lack of timeliness and completeness, document loss or damage due to weather and insects, and the physical space required to store paper-based maintenance reports have been effectively eliminated. Workers are able to access and retrieve information easily. Data quality has improved significantly by receiving feedback on data errors from the field. Over 38,000 data discrepancies between field observations and the GIS database have been resolved.

The team implemented a performance assessment solution for the maintenance contractors and field crews. The solution met the corporate auditor’s requirements. The solution streamlined and unified the business process of field maintenance activities and improved its efficiency and effectiveness.

GIS at MZEC can solve problems and return what was invested in system creation and data collection

Benefits

The project exceeded the initial goal of completely modernizing MZEC’s maintenance and inspection workflows. What the team did not expect, however, was that the project and its success would encourage other departments to see how GIS could benefit their own workflows. Examples included implementing applications to address risky connections, physical security problems, and issues with substation load records.

The solution aligns with MZEC’s strategy to improve business process efficiency and effectiveness, cutting costs and time, going green, and implementing innovation and digital transformation. As a result, MZEC gained insight into the health of its assets. The solution also provided the users with a solid foundation for further analysis.

The solution helps the assets team answer critical questions easily. What and where are the assets that need urgent preventive maintenance? How many materials are required for the maintenance plan? How is the field crew being utilized, and what is its performance?

With the solution, MZEC can review—through various dashboards—the current electrical asset conditions and support decision-making based on deep analysis.

The project and its success improved the credibility and acceptance of GIS as the main asset information source. Further, it established the GIS team as a trusted and active organization that can help overcome core business challenges in the company.

“Harnessing the power of digitization and capitalizing on our distinguished IT capabilities, GIS is always at the core of what Mazoon Electricity Company does.”

Mohammed Al Ghenaimi

Senior Manager, Planning and Asset Management, MZEC