Facility Mapping of Infrastructure

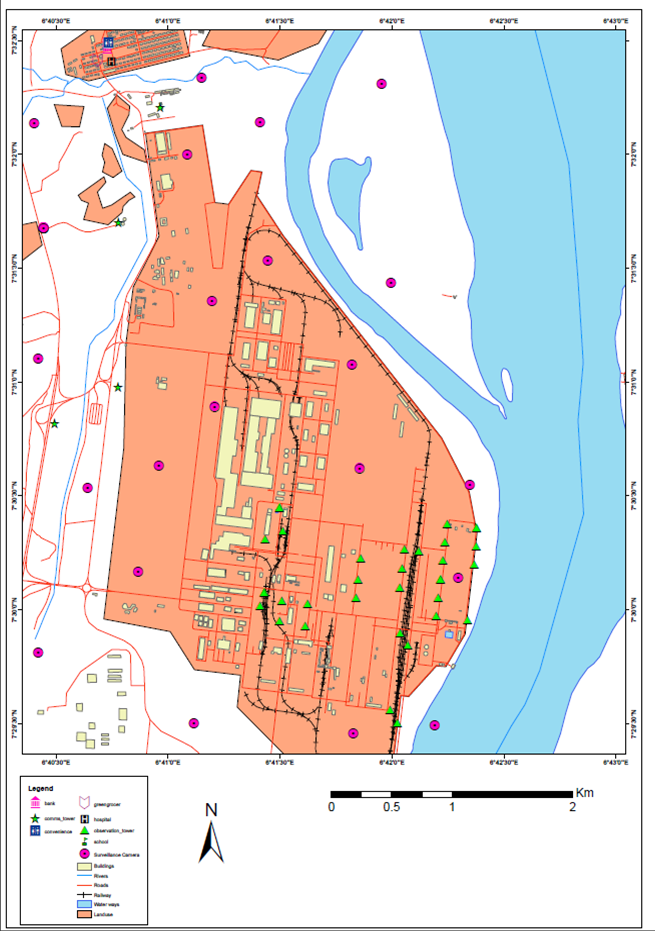

Facility Mapping of Infrastructure: A case study of Ajaokuta Steel Company, Kogi State Nigeria.

The precise location of every aspect of infrastructure, from what is underground to what is overhead, is easier to discern and understand using geospatial information and technologies. Fortunately, tremendous advances in geospatial technologies have made these tools far more powerful, accessible, and usable—many of which have been driven by the commercial sector, including Esri.

Using technologies such as intelligent, real-time GIS and GPS maps to prioritize, plan, and execute new infrastructure projects can help public and private infrastructure investments be more efficient and reduce waste.

Maps made with GIS, GPS, and aerial imagery can be quickly created and updated. They also usually include detailed information not only about current and planned infrastructure improvements but also about the contexts in which they are being implemented. For example, if a local government wants to see all the potholes in its downtown area mapped out, it can use GIS to do so—and then add useful data layers like traffic flow and pavement type to figure out what’s causing them and how to prevent them in the future. To improve project planning and operations, these maps can be shared digitally across sectors.

This project aims to display the powerful use of Esri GIS Software for mapping Ajaokuta steel rolling mills.

The Study Area

Ajaokuta Steel Company is Nigeria’s leading steel company. Guided by a philosophy to produce safe, sustainable steel, it is the leading supplier of quality steel products in all the major economic sectors including the construction, packaging, and wire drawing/nail making industry. ASCL operates in all the major markets in Nigeria and employs about 3000 people.

The Federal Government of Nigeria established the Nigerian Steel Development Authority (NSDA) in 1971 through Decree No. 19 in order to advance the development of the Nigerian Steel Industry.

NSDA carried out detailed market studies and investigations on the availability of local raw materials. The Preliminary Project Report (PPR) of 1974, the Detailed Project Report (DPR) of 1977, and the Global Contract (1979) for construction of the steel plant at Ajaokuta were all commissioned and executed during the NSDA period.

The NSDA was thereafter dissolved through decree; No. 60 on the 18th of September 1979. This decree also created Ajaokuta Steel Company Limited, ASCL being the successor of NSDA.

The Ajaokuta integrated steel complex was conceived and steadily developed with the vision of erecting a Metallurgical Process Plant cum Engineering Complex with other auxiliaries and facilities.

The complex is meant to be used to generate important upstream and downstream industrial and economic activities that are critical to the diversification of our economy into an industrial one. Ajaokuta Steel Plant is therefore aptly tagged as the “Bedrock of Nigeria’s industrialization”.

The project was embarked upon as a strategic industry, a job creator, and a foreign exchange saver and earner. It was envisaged that the project would generate a myriad of socio-economic benefits and increase the productive capacity of the nation through its linkages to other industrial sectors. It would provide materials for infrastructural development, technology acquisition, human capacity building, income distribution, regional development, and employment generation. While the project would directly employ about 10,000 staff at the first phase of commissioning, the upstream and downstream industries that will evolve all over the nation will engage not less than 500,000 employees.

The plant by 1994 was reckoned to be at 98% completion in terms of equipment erected. Some completed units of the Plant operated at different times but had to short down due to the non-availability of funds.

Project by: Tesini Precious Dombo – tdombo@sambusgeospatial.com

SOFTWARE: ArcGIS Pro 2.7.2

DATA SOURCE: Esri Imagery Basemap. Ancillary Data of the existing Infrastructure